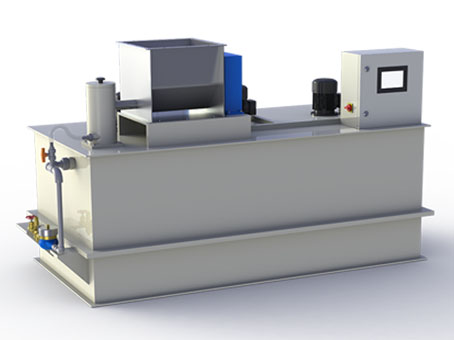

α-Power Series hydraulically actuated diaphragm metering pump

α-Power Series hydraulically actuated diaphragm metering pump

is a high-accuracy ,compact hydraulic diaphragm metering pump designed and manufactured according to the API 675 requirements. It is suitable for the application in various demanding and complicated process condition, with the advantages of compact structure and easy maintenance. Mainly applied in power supply, chemistry, petro-chemistry, papermaking,textile, green energy and environmental protection, could be used in bio-pharmaceutical and food industry as well.

Typical Dosing Applications:

Ammonia、Hydrazine、Scale inhibitor、Water treatment additives、Chemical process additives、Oli industry additives、Edible pigment and food flavor Technical Specification

.Flow rate: 1.6~326/h

.Max.discharge pressure: 160 Bar

.Turndown Ratio: 10:1

.Stability accuracy: ±1%

.Max. liquid temperature: 90℃

.Max. viscosity: up to 1200cP

The Technical Features

● Designed for continuous operation for various special fluid delivery

● Various wetted materials available for the pump: 316SS, PVC, PVDF, special alloys, etc.

● Tight seal of diaphragm ensures no leakage

● Various detective modes : diaphragm with gauge pressure switch transmitter, etc.

● Internal pressure relief valve provides over-pressure ,automatic refill system ensures the stability of output flow rate and meets the accuracy

Requirements

● Various check valve options: single-ball valve, double-ball valve, spring loaded valve

● Various connection options: threaded connection, flange connection

● Pump stroke can be adjusted from 0% to 100% wether pump running or stopping

● Accuracy:±1%, turndown ratio:10:1

● Conical roller-bearig suits high loads operation

● Oil bath lubrication ensures low wear and high reliability

● High-efficiency worm/ gear reducing device works steadily with low noise

● Compact structure and small size, suits for small installation space

● The design and manufacture complies with the API675 standards

Flow rate adjustment methods

Manual adjustment: change the stroke length through knob from 0% to 100%

● Adjusting flow rate either running or stopping

● Minimum adjustment scale is 1%

Electric capacity controller: adjusting stroke length following external signal

● Power source: 220V-50Hz-single phase

● Input signal: 4-20mA

● Output signal: 4-20mA

● Frequency conversion controller: adjusting stroke speed following external signal

● Power supply: 220V-50Hz-single phase or 380V-50Hz-three phase

● Input signal: 4-20mA