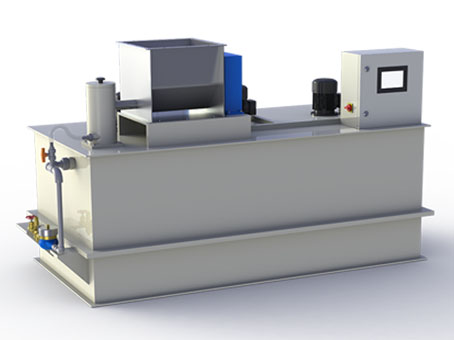

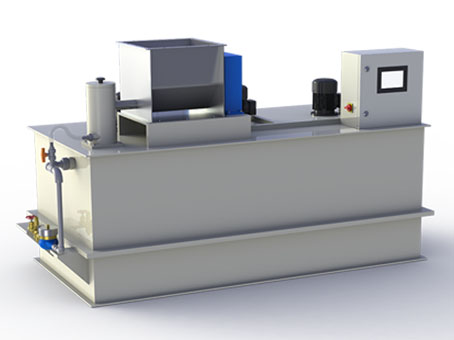

HYBRIDOSE SOLUTION PREPARATION UNIT

HYBRIDOSE SOLUTION PREPARATION UNIT is used for the polymer or flocculant solution preparation. It sets up a continuous working process from powder to solution with static concentration through powder feeding, water supply, dissolving, maturing and storage. It can combine with metering pump or screw pump to dose prepared solution into injection point continuously. It has advantage of small size, simply operation and easy installation.

Typical application:

Municipal water treatment and waste-water treatment

Industrial waste water treatment

Sludge dewatering

Cement

Pulp paper

Food industry

Chemical industry

Unit Structure:

Powder Feeding: Hopper-1, Screw feeder-2, Reducer & Motor-3, Vibrator (option)

Water Supply: Shut-off valve-4, Pressure Reducing Valve-5, Solenoid Valve, Flowmeter-6, Powder Wetting assembly-7

Tank: Dissolving tank, Maturing tank, Storage tank

Agitators: Dissolving agitator, Maturing agitator, Storage agitator (option, timing control)

Control panel: Local/Remote control, Powder level detection & control, Liquid level detection & control, alarm output

Model Selection:

Treatment Flow Rate: 1000 m3/h

Concentration after dosing: 2ppm

Required Polymer powder quality: 1,000,000 x (5/1,000,000) = 2 Kg/h

Polymer solution concentration: 2g/L

Polymer solution requirement: 2 Kg/h / 2g/L = 1000 L/h

Maturing time: 1 hour

Recommended Model: HD1000