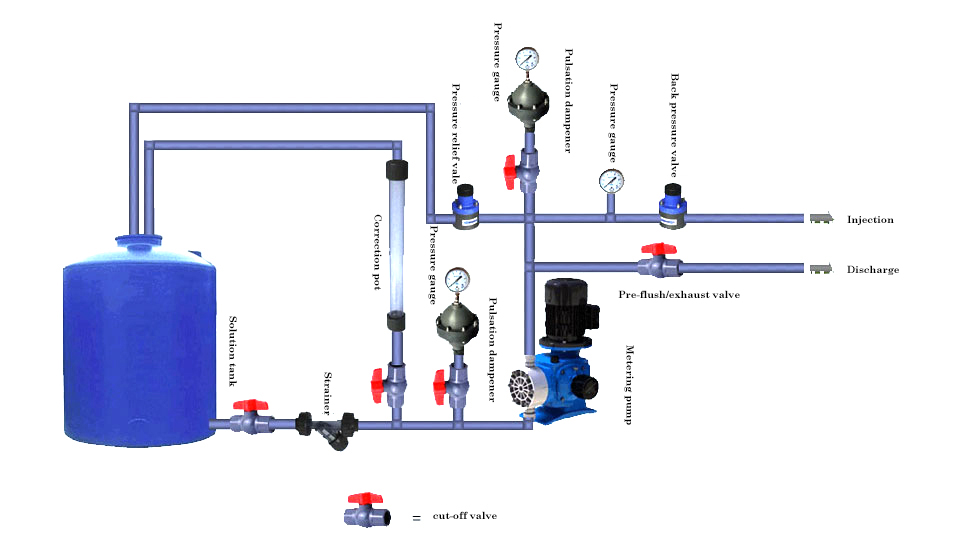

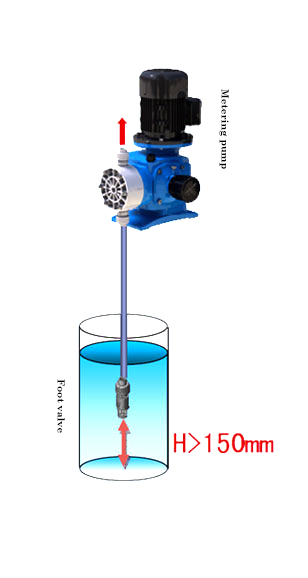

| Inlet piping requirements: 1. The suction end of the pump must be lower than the lowest liquid level of the reservoir, so that the suction side of the pump can be pumped directly into the liquid. In order to reduce the loss of the metering pump suction pipe, the metering pump installation position should be as close to the solution tank as possible. 2. The negative pressure suction condition (suction process) should be avoided, which can affect the measurement accuracy and influence the accuracy of measurement. The suction height of pump is directly related to the structure of pump, the characteristics of material medium (density, viscosity, etc.). If you need to know the specific data, you will need to provide the pump type, material characteristics and system parameters, which will be assisted by the professional staff. 3. Ensure that the pump is operating under atmospheric pressure or above atmospheric pressure. If the pump runs under pressure below atmospheric pressure, under negative pressure condition, ensure no leakage of all the joint parts, and the foot valve is installed at the bottom of the suction line. 4. Due to the impact of the head loss of the acceleration and the flow loss of the pipeline, the diameter of the suction line should be greater than the inlet of the pump head, so as to avoid the shortage of the pump. If the inlet line is short and the piping layout is flat and straight, the pipe diameter of the inlet line is at least one gear larger than the metering pump inlet size. If the inlet line is long and the piping layout is more tortuous, there are more elbow, tee and valve, then the pipe diameter of the inlet line is at least two times larger than the metering pump inlet size. 5. When conveying materials close to boiling point, adequate suction pressure should be provided to avoid the vaporization of the material when it enters the pump head in the suction stroke. 6. The inlet line should be made of metal or plastic tubing as far as possible. The tube has a smooth inner wall and a large radius to reduce the flow friction loss. 7. The inlet line should use the strainer to avoid the external particles entering the pump head.To avoid debris entering and obstructing the one-way valve ball and improve the degree of maintenance, the strainer should be checked frequently. 8. When the long distance suction line must be used, a vertical riser should be installed in the suction line near the pump. 9. The suction line must be absolutely airtight to ensure accurate flow. After the pipeline is installed, test the suction pipeline with air and soap to leak. |

Export pipeline requirements:

1. The pipe diameter of the outlet pipe must be large enough to avoid excessive pressure loss in the pump discharge stroke. The maximum pressure capacity of the outlet pipe of the pump head must be maintained at or below the maximum allowable pressure value indicated on the pump sign.

2. In a system with low system pressure, it is recommended to install backpressure valve. Adequate differential pressure (about 0.2mpa) must be maintained between the outlet of the pump and the entrance. If the pressure difference between the pump outlet and the inlet is too small or no pressure difference, it can affect the output flow of the pump and even the siphon phenomenon.

3. For system pressure above 0.5 MPa, there is no need to install backpressure valve in the outlet pipeline.

4. It is recommended to install pulsation buffer in the outlet pipeline of the pump to reduce the system impact caused by flow fluctuation. The pulsating buffer can control the pump outlet flow pulse at plus or minus 10% range. Select a good buffer that can control the pulse at plus or minus 2 percent. If not installed pulsation dampeners export pipeline pump is used to export the diameter of the same size of the pump pulse flow characteristic of pipeline vibration and impact, causing instrument damage in the pipeline, pipeline rupture and pipeline vibration noise. At the same time, the system output flux is unstable.

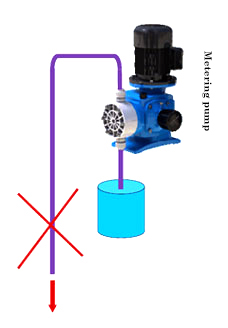

Error installation method :

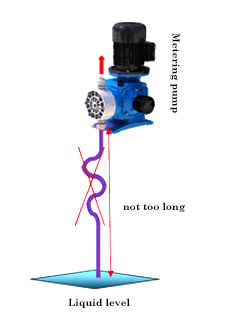

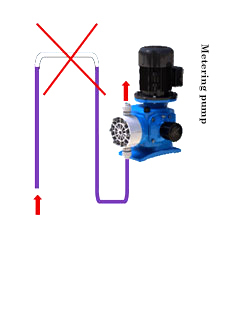

1. The inlet line should not be long. If it is to upgrade the installation mode, the height should not be too high. Both methods increase the pressure loss of the inlet line, which can lead to cavitation. Solution: 1) Change the installation position of the pump, increase the length of the outlet pipeline and shorten the length of the inlet pipeline; 2) Enlarge the pipe diameter of inlet pipe, reduce the pipe loss caused by inlet line, avoid cavitation phenomenon. |  2. The pipe at the top of the inlet pipe has a buildup of gas, resulting in the failure of normal suction. Solution: 1) Change the position of the inlet line of the pump and exit the inlet line from the bottom of the tank; 2) Adopt the lifting installation scheme and add the foot valve at the bottom of the inlet line. |

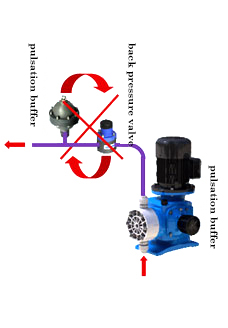

3. Why siphoning phenomenon occurs is that there is no sufficient pressure difference between the outlet of the pump and the inlet, and the solution still flows from the entrance to the outlet when the pump is stopping. Solution: 1) Install the back pressure valve and artificially create pressure difference in the pump outlet line.Prevent siphonage. |  4. The pulsation buffer installation position is incorrect, causing the buffer not to function normally. Solution: 1) Exchange the position of pulsation buffer and back pressure valve. Install the buffer upstream of the back pressure valve. |